CMT-Motores Térmicos

With over 40 years of experience in transportation, CMT is now combining expertise in advanced low temperature combustion, synthetic fuels and hybridization to attain deep transport decarbonization.

Contact information

Dr. Antonio García (angarma8@mot.upv.es)

Phone: +34 963876559

Fax: +34 963876559

The success of CMT and its projects is built upon teamwork and close relationships with leading OEMs. Within the organization, the compression ignition combustion and hybrid investigation teams are combining low temperature combustion with synthetic fuels and hybridization to attain deep transport decarbonization. The following provides details on a collaborative project including CMT-Motores Térmicos, Aramco Overseas and Volvo GTT.

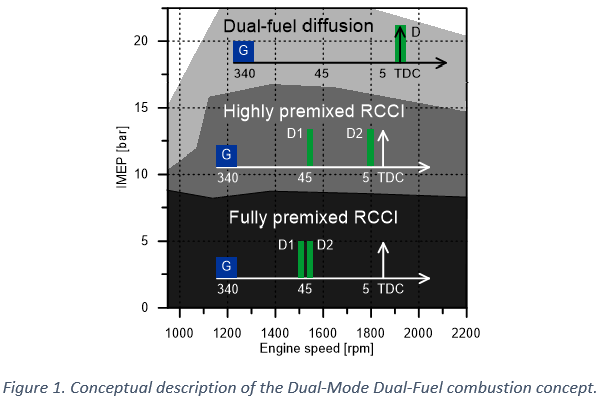

The combustion research group has been working on extending the benefits of low-temperature combustion for several years. This effort has led to the development of the “Dual-Mode Dual-Fuel (DMDF)” combustion concept. Figure 1 provides a conceptual description. The combustion mode relies on exploring the benefits of the fully premixed RCCI combustion to the greatest extent. Nevertheless, as the combustion starts to be limited by pressure gradients, the in-cylinder equivalence ratio stratification is increased by means of modifying the injection timing of the high reactivity fuel.

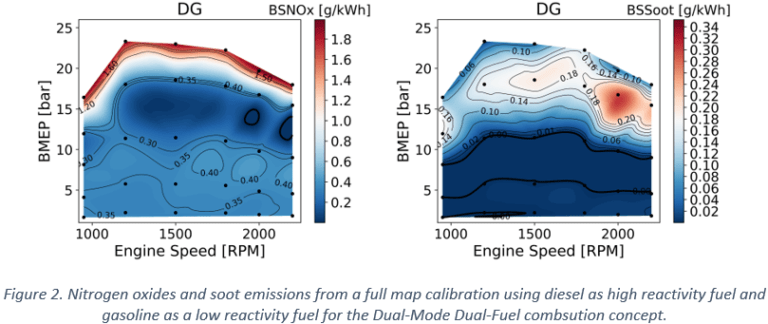

Figure 2 shows the benefits of DMDF on lowering engine-out NOx and soot emissions, while using gasoline and diesel as low and high reactivity fuel respectively whereas. The use of low-temperature combustion helps lower engine-out NOx emissions by an order of magnitude compared to conventional diesel combustion, helping meet the EU VI requirements across most of the engine map. Soot emissions are also practically zero wherever a fully premixed combustion is employed, with penalization as the combustion is shifted to a diffusive one. It is worth mentioning that fuel consumption is not penalized compared to the original conventional diesel calibration, despite lowering the compression ratio by 5 points.

Current regulations in Europe require solutions that can provide 15% of fuel consumption reduction by 2025 and 30% by 2030. The use of synthetic fuels is well aligned with this scenario since they are produced combining renewable energy and having CO2 as one of the raw materials in the process.

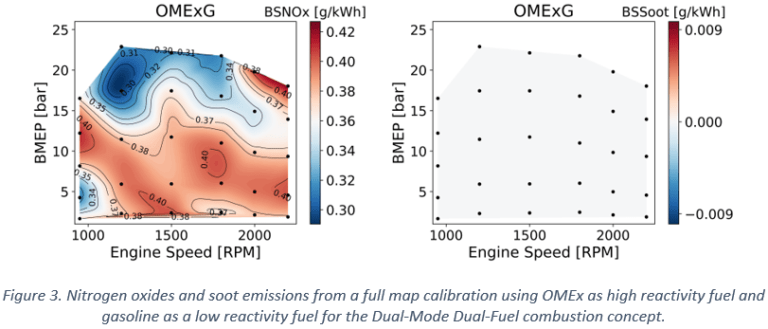

In this sense, a high oxygen synthetic fuel (Oxymethylene dimethyl Ether – OMEx) was selected to replace diesel, given its similarities with respect to diesel in terms of fuel injection system requirements. Additionally, the high oxygen content enables to solve one of the limitations from the DMDF combustion: the high demand on the air management system.

Figure 3 shows that the use of OMEx reduced soot formation while enabling the use of high exhaust gas recirculation (EGR) levels to tailor the NOx emissions.

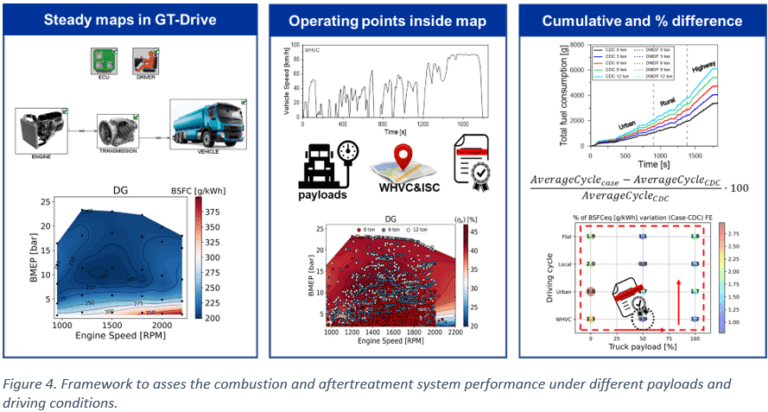

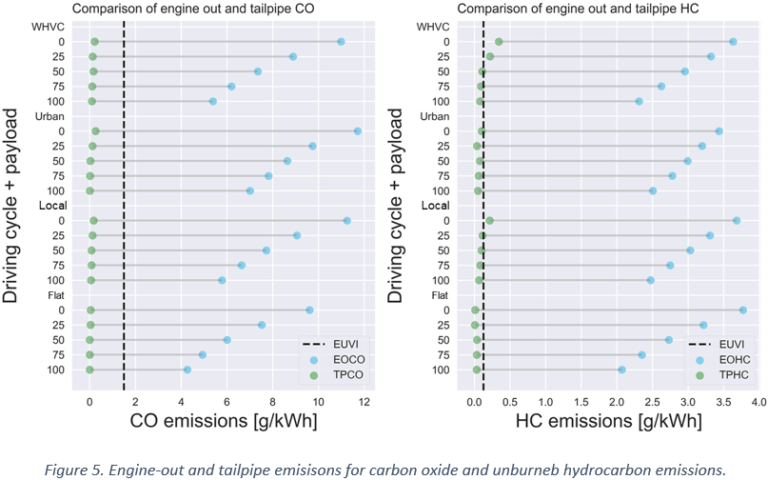

The emissions results show the possibility to significantly downsize or eliminate the selective catalytic reduction (SCR) and diesel particulate filter (DPF) systems, enabling a significant cost reduction associated with after-treatment system production and operation. However, as with any low-temperature combustion concept, the DMDF presents a significant concentration of unburned products which pose a challenge for the oxidation catalyst (OC). Specific investigations were performed under steady-state conditions and through drive cycle simulations to understand the impact on the OC performance. Figure 4 shows the framework built using the GT-Suite® package for the simulations.

The results of the analysis, illustrated in Figure 5, suggests that the oxidation catalyst system is not sufficient to meet the regulatory limits at the 0% payload scenario. Nevertheless, as the truck payload increases, the operating conditions move to high engine loads, enhancing the conversion efficiency due to the higher exhaust temperature. At payloads > 50% (representative of homologation conditions), the oxidation catalyst complies with the regulation requirements.

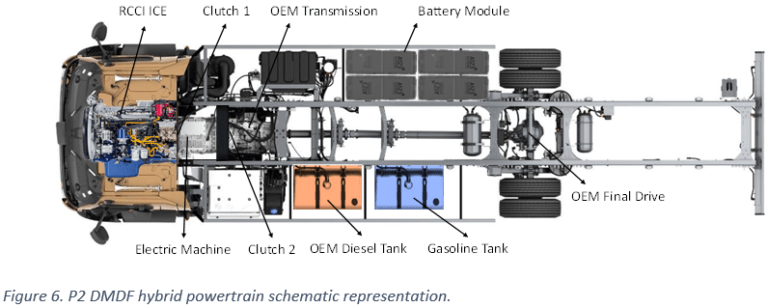

An additional step towards the CO2 reduction includes hybridization of the powertrain. Additional benefits can also be achieved such as engine derating, which may allow to operate only in the fully premixed part of the map. Having these considerations in mind, an exhaustive investigation was performed to design a suitable electrified powertrain addressing battery and electric motor sizing as well as the best hybrid powertrain architectures to be used for truck application. Figure 6 shows the parallel P2 hybrid powertrain developed.

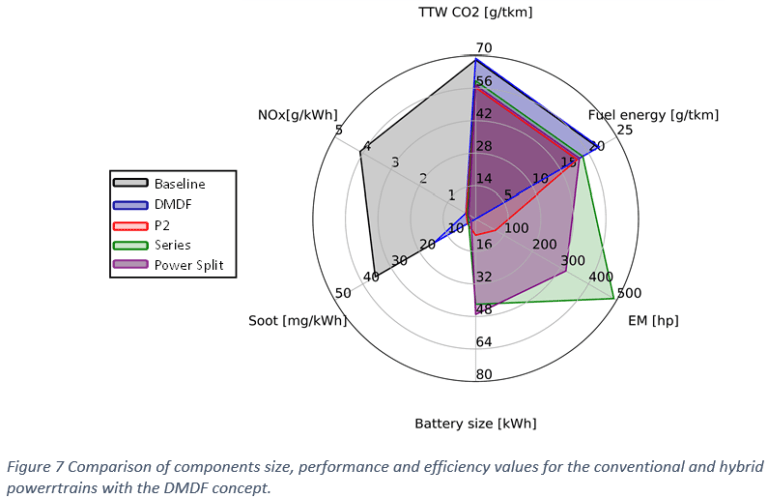

Several different hybrid architectures have been proposed in the literature, such as series, power split and parallel. A design process was performed to determine the optimum component size for each of the architectures and the maximum benefits that can be extracted considering fuel consumption, CO2 reduction and emissions. As summarized in Figure 7, the P2 hybrid powertrain was found to offer the best overall solution. It combines the highest benefits on energy savings with ultra-low NOx and soot emissions, while requiring reduced size of battery and electric motors compared to the other hybrid powertrains.

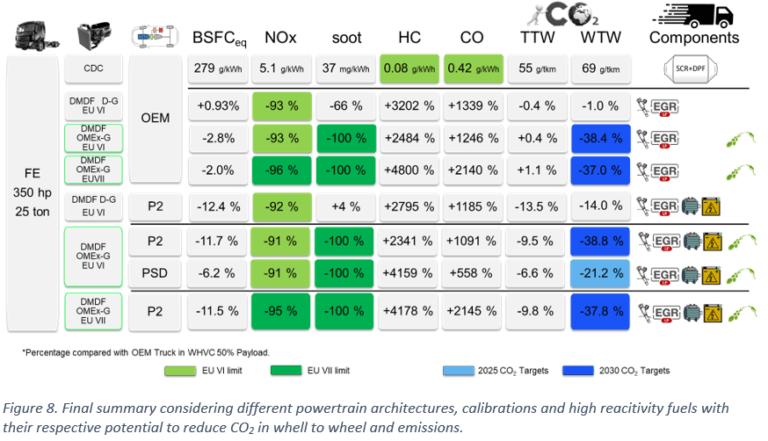

An overall summary of the results obtained in this investigation is presented in Figure 8 along with listing the components required in each powertrain.

It can be concluded that the use of synthetic fuels produced from a green pathway combined with any type of powertrain allows to attain at least the 2025 targets for CO2 emissions. This is done while also reducing soot and NOx emissions that can fulfill the current EUVI regulation.

Despite many speculations about the end of the internal combustion engine in the next few years, a realistic approach must be pursued. The first step towards a non-biased view is the inclusion of wells-to-wheel (WtW) regulations, which will certainly place the use of synthetic fuels as a direct alternative to decarbonize transportation at the fast pace that is required. Additionally, the use of hybrid powertrains is a solution needs to be considered, since it offers energy flexibility and reducing some of the barriers facing fully electric vehicles in the commercial transportation sector.

CMT- Motores Térmicos believes in real transport decarbonization and will continue pushing towards this direction using its state-of-the-art facilities and expertise.

If you are interested in being part of the team or develop research investigations together, don’t hesitate to contact us here:

Contact Information

Dr. Antonio García (angarma8@mot.upv.es)

Phone: +34 963876559

Fax: +34 963876559

Representative papers

[1] García A, Monsalve-Serrano J, Lago Sari R, Gaillard P. Assessment of a complete truck operating under dual-mode dual-fuel combustion in real life applications: Performance and emissions analysis. Appl Energy 2020;279:115729. https://doi.org/10.1016/j.apenergy.2020.115729.

[2] García A, Monsalve-Serrano J, Martinez-Boggio S, Gaillard P, Poussin O, Amer AA. Dual fuel combustion and hybrid electric powertrains as potential solution to achieve 2025 emissions targets in medium duty trucks sector. Energy Convers Manag 2020;224:113320. https://doi.org/10.1016/j.enconman.2020.113320.

[3] Pastor J V., García A, Micó C, Lewiski F. An optical investigation of Fischer-Tropsch diesel and Oxymethylene dimethyl ether impact on combustion process for CI engines. Appl Energy 2020;260:114238. https://doi.org/10.1016/j.apenergy.2019.114238.

[4] Benajes J, García A, Monsalve-Serrano J, Martínez-Boggio S. Potential of using OMEx as substitute of diesel in the dual-fuel combustion mode to reduce the global CO2 emissions. Transp Eng 2020;1:100001. https://doi.org/10.1016/j.treng.2020.01.001.

[5] Luján JM, García A, Monsalve-Serrano J, Martínez-Boggio S. Effectiveness of hybrid powertrains to reduce the fuel consumption and NOx emissions of a Euro 6d-temp diesel engine under real-life driving conditions. Energy Convers Manag 2019;199:111987. https://doi.org/10.1016/j.enconman.2019.111987.

[6] García A, Monsalve-Serrano J, José Sanchís E, Fogué-Robles Á. Exploration of suitable injector configuration for dual-mode dual-fuel engine with diesel and OMEx as high reactivity fuels. Fuel 2020;280:118670. https://doi.org/10.1016/j.fuel.2020.118670.

[7] Macián V, Monsalve-Serrano J, Villalta D, Fogué-Robles Á. Extending the potential of the dual-mode dual-fuel combustion towards the prospective EURO VII emissions limits using gasoline and OMEx. Energy Convers Manag 2021;233. https://doi.org/10.1016/j.enconman.2021.113927.

[8] Benajes J, García A, Monsalve-Serrano J, Lago Sari R. Experimental investigation on the efficiency of a diesel oxidation catalyst in a medium-duty multi-cylinder RCCI engine. Energy Convers Manag 2018;176:1–10. https://doi.org/10.1016/j.enconman.2018.09.016.

[9] Benajes J, García A, Monsalve-Serrano J, Sari R. Clean and efficient dual-fuel combustion using OMEx as high reactivity fuel: Comparison to diesel-gasoline calibration. Energy Convers Manag 2020;216:112953. https://doi.org/10.1016/j.enconman.2020.112953.

CMT-Motores Térmicos

CMT-Motores Térmicos With over 40 years of experience in transportation, CMT is now combining expertise in advanced low temperature combustion, synthetic fuels and hybridization to

Super Ultra Low Energy and Emission Vehicle (SULEEV) Center

Centers of excellence around the world on clean mobility technologies Super Ultra Low Energy and Emission Vehicle (SULEEV) Center SULEEV (Super Ultra Low Energy and