Conference Presentation Summary

Direct manufacturing cost of BEV vs ICE

Reference: FEV Consulting Inc., U.S. EPA, 45th International Vienna Motor Symposium

Background

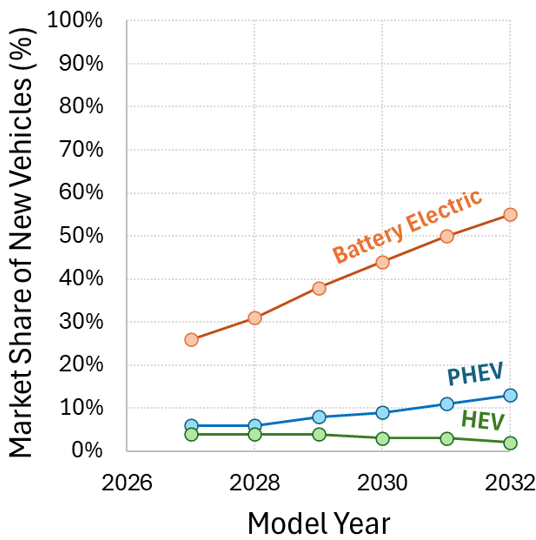

The U.S. EPA has established stringent CO2 tailpipe limits for passenger cars and medium-duty vehicles starting M 2027. We have covered these in an earlier post. The rule will require a fleet averaged 50% reduction in CO2 emissions for light-duty vehicles, over MY 2027 – 2032. The rule, while technology neutral, is clearly expected to promote electrification, and by EPA estimates (shown in the figure) over half of the new vehicle sales will be fully battery electric by 2032.

The EPA, in setting such rules, analyze the cost-effectiveness of new technologies. In a talk delivered at the Vienna Symposium, an example of such an analysis was provided, and we summarize it here. Note that this is limited to direct manufacturing cost, does not cover the markups leading to end customer price and also any reference to the CO2 reduction potential.

Sign up here to receive such summaries and a monthly newsletter highlighting the latest developments in transport decarbonization

5-Min Monthly

Sign-up to receive newsletter via email

Thank you!

You have successfully joined our subscriber list.

Recent Posts

EPA Demands Manufacturer Data as It Expands Action on DEF System Failures

![]()

A brief summary of recent EPA changes to DEF-related failures.

EPA repeals 2009 GHG endangerment finding

![]()

The US EPA is repealing the 2009 GHG endangerment finding and terminating all vehicular GHG standards.

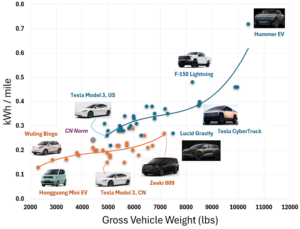

Efficiency of EVs in US and China

![]()

China has set energy efficiency norms for electric vehicles – how do modern EVs fare?