Achieving 90% reduction in NOx emissions from heavy-duty vehicles

California’s Low NOx Omnibus will be phased in through model years 2024 – 2031 and will require >90% reductions in tailpipe NOx emissions from heavy-duty trucks. This is a high-level summary of a multi-year program led by Southwest Research Institute to demonstrate the feasibility of achieving these targets.

Background

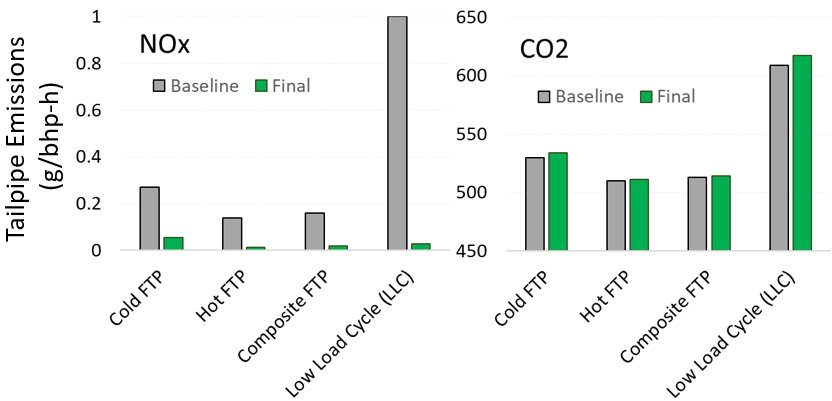

Starting back in 2014, California’s Air Resources Board (CARB) initiated a program to evaluate the feasibility of reducing tailpipe NOx emissions from heavy-duty vehicles by 90%. Southwest Research Institute (SWRI) has led this comprehensive study in three stages, through implementation of advanced engine and after-treatment solutions. A key objective of the study was to demonstrate meeting the upcoming NOx standards without incurring a significant fuel or CO2 penalty.

For a quick overview of California’s low NOx Omnibus rule starting 2024, the reader is referred to this link.

Summary

A combination of modified engine calibration, implementation of new hardware and an advanced after-treatment system with close-coupled catalyst was implemented. After accelerated aging representative of 435,000 miles, the final tailpipe levels were at 0.02 g/bhp-h on the FTP cycle, right at the Low NOx Omnibus target. Even on the challenging low load cycle, NOx emissions are at only 0.029 g/bhp-h. What is remarkable is that CO2 emissions were practically unchanged except for the low load cycle, where the CO2 emissions increased by ~ 1%.

Key Enabling Technologies

Advanced engine calibration and hardware

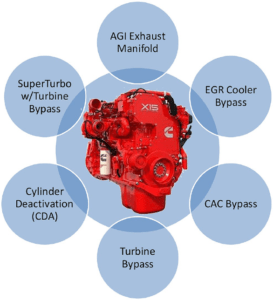

The baseline engine was a Cummins 15L in-line 6 cylinder engine. The open ECU allowed the team to make several modifications to the engine calibration, such as elevating the idling speed for rapid thermal warm-up. Still, new hardware had to be added to further elevate the exhaust gas temperature (for early SCR activation) – without imposing a fuel penalty. Some of these are shown in the figure and will be covered in detail in other articles. A couple of technologies are highlighted:

- Cylinder deactivation (supplied by Eaton) reduces fuel consumption while also raising exhaust temperature through independently deactivating any of the cylinders under reduced load.

- SuperTurbo is a driven turbocharger which can mechanically transfer power to and from the turbo shaft enabling compounding of excess turbine energy. For more information on SuperTurbo, read here.

Light-off SCR, model-based controls and aging

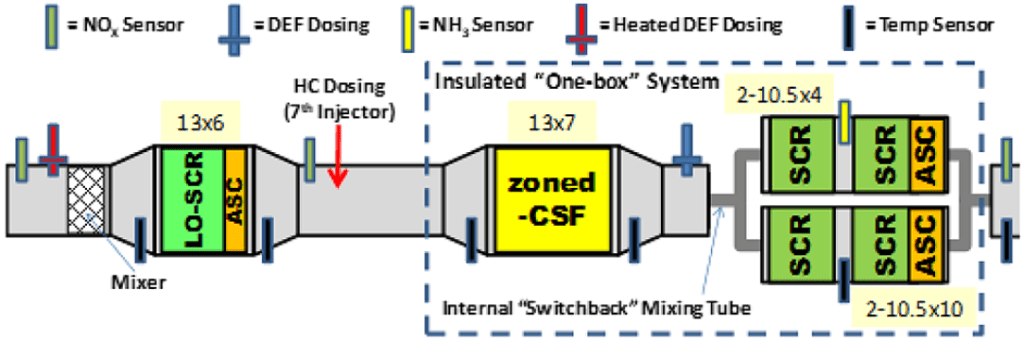

- An advanced after-treatment was implemented including a “light-off” SCR in the close-coupled position for early heat-up of the catalyst. This and the downstream SCR had separate urea dosing. While a catalyzed soot filter with a zoned DOC coating was implemented and showed promise, a recent rework has also examined the use of a separate DOC + DPF system with even better results.

- A critical part of improved after-treatment operation was the implementation of model-based control of the diesel exhaust fluid (DEF) dosing and the associated estimation of ammonia coverage for each SCR unit.

- Aging to 435,000 miles is not trivial. This was done using an accelerated protocol – still requiring 1000 hours of engine operation – to capture both hydrothermal and chemical aging.

For more information read SAE 2021-01-0589, doi:10.4271/2021-01-0589

Like it ? Share it !